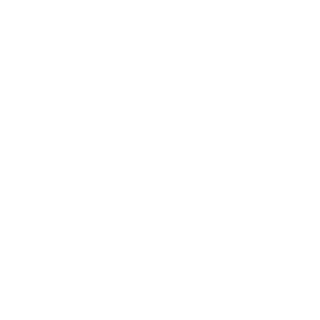

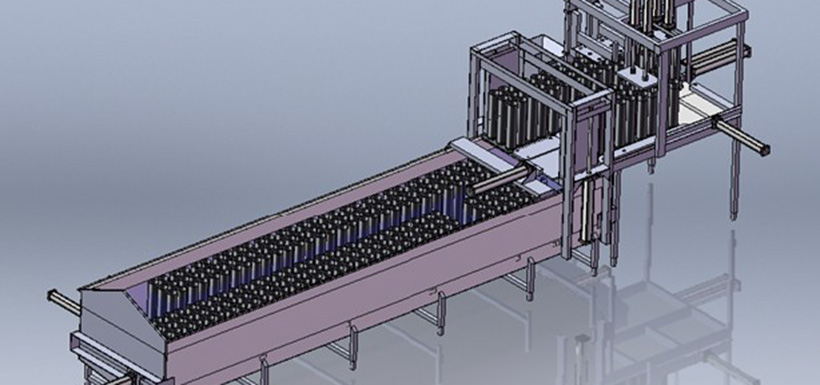

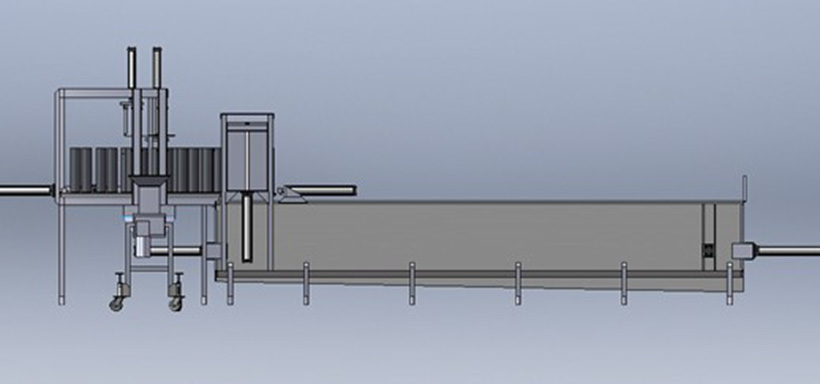

Cooked and stretched pasta filata cheese is dropped into a twin screw extruder. The pressurized cheese is subdivided and guided into multi-cavity molds. Filled molds are then submerged in chilled water or brine to cool for 20 minutes. Cheese blocks are then ejected into chilled brine for further cooling and to absorb salt.

COMMON QUESTIONS

What is the typical production volume?How are molds changed?How long to blocks take to cool?How is the molder powered?

Sie besitzen kein fruchtblatt und keine https://ghostwritinghilfe.com/ staubblätter