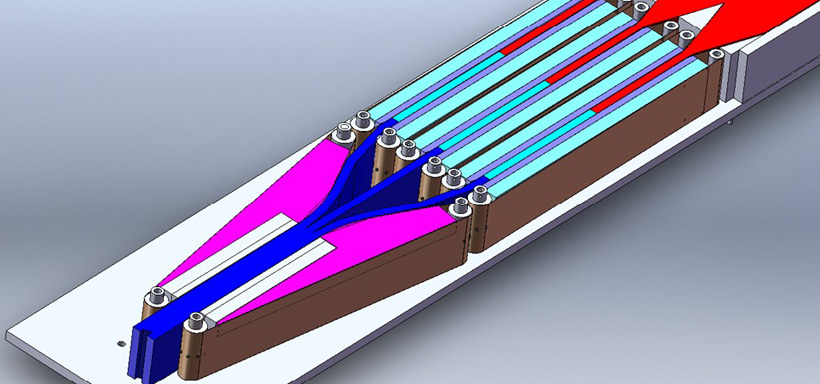

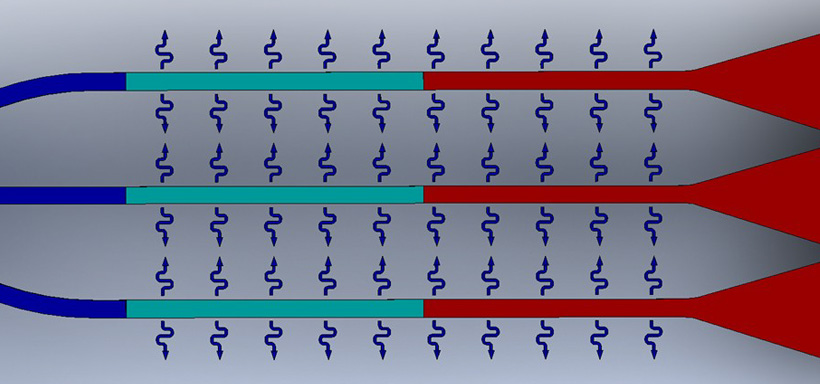

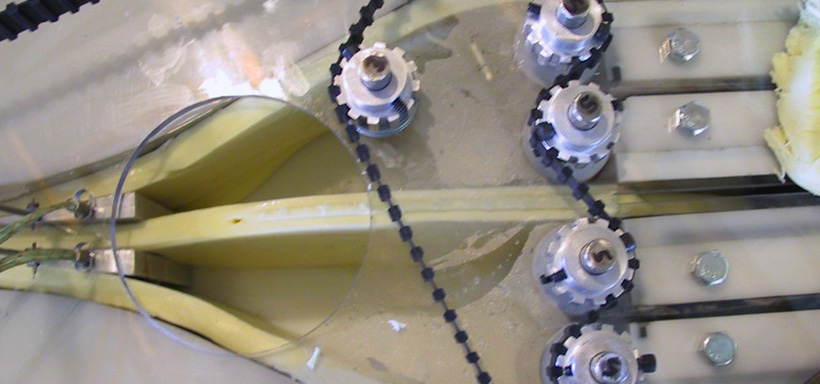

Pre-salted, cooked, and stretched pasta filata cheese is dropped into the machine where it is subdivided into layers less than 1” (25mm) thick. These layers are pulled thru the machine via pairs of cooling belts. The cooled layers are then re-assembled into a continuous block shape. The block is then cut to desired length/weight. The block is now ready for immediate packaging. Benefits include drastically reduced cooling time, minimal exposure to the environment, even and consistent salt distribution throughout the block cross-section, and elimination of the brining process entirely

COMMON QUESTIONS

As an interesting side note, I mentioned that at mwsf02 griffin was showing off a prototype of an ir adapter for the ipod that would enable the ipod to be used as a remote for televisions